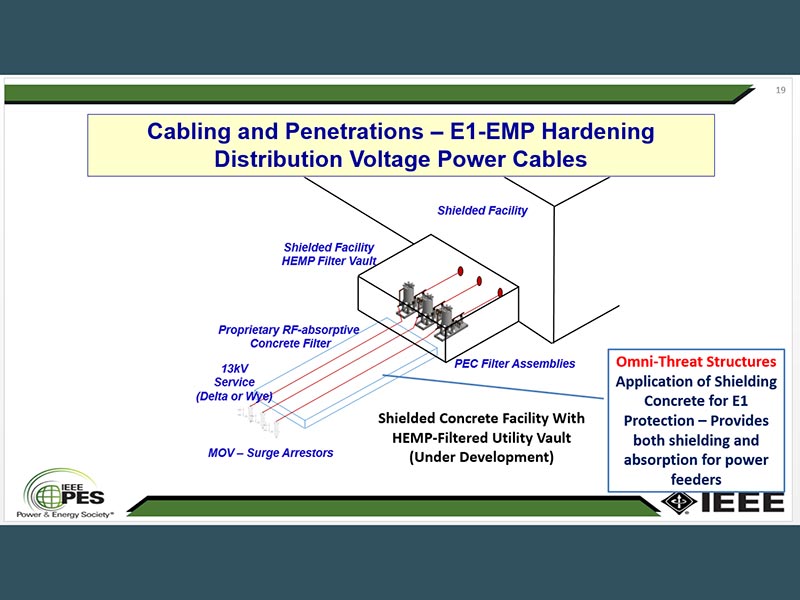

While R&D is ongoing, the successful outcomes to date include threat configurable electromagnetic shielding being integrated into multi-threat resistant structures; HEMP, IEMI and Tempest configurable shielding systems; material components optimized for shielding effectiveness and construction methods that enable shielding effectiveness and cost reduction. Other recent initiatives include:

As part of our on-going R&D and continuing drive for lower cost structures, OTS constructed a prototype building, OTS Integrated Shielded Test Structure, to validate the next generation of OTS EMSS materials and methods. We provided further proof that the shielded envelope can be 10 inches instead of the previous 12 inches.

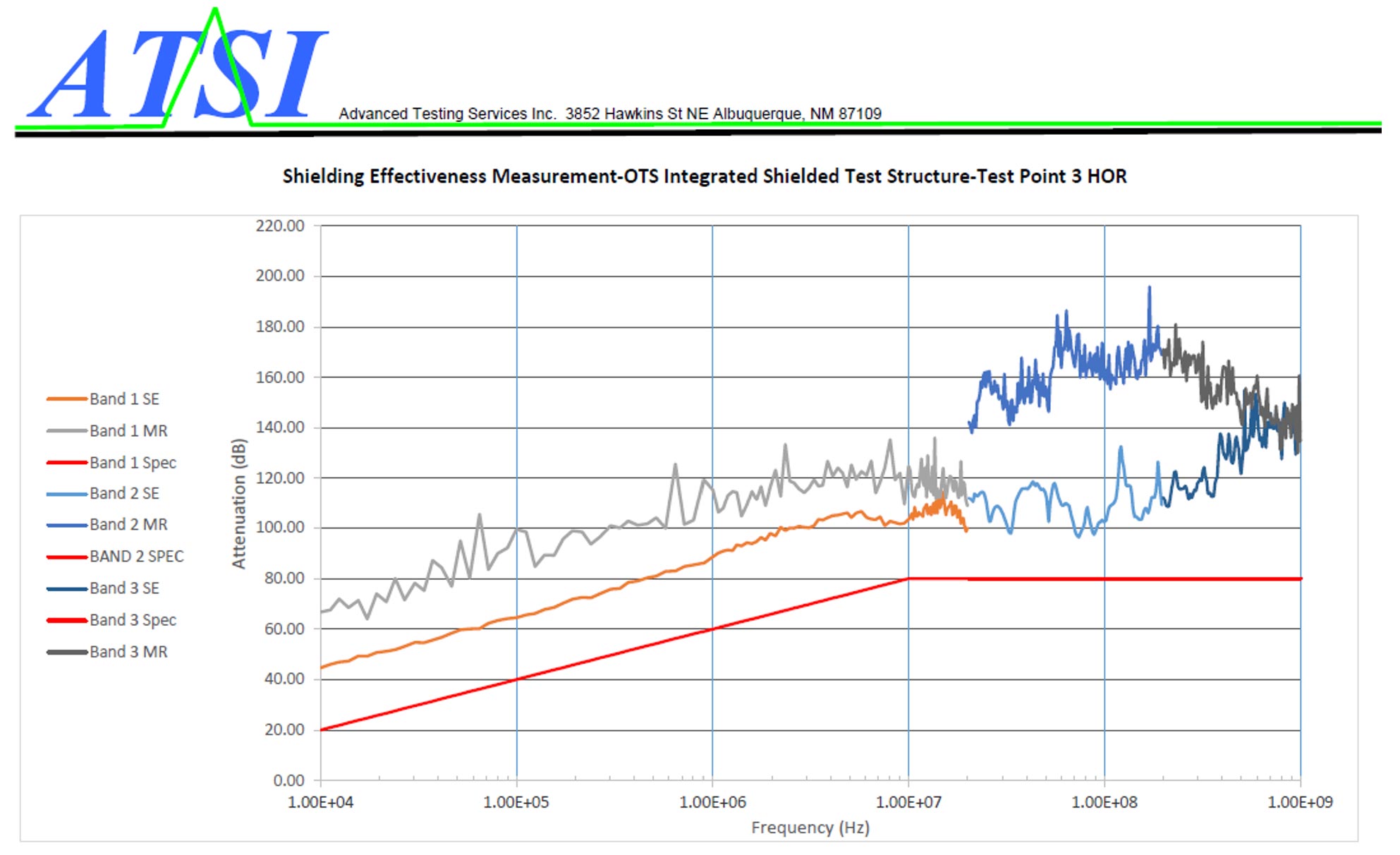

ATSI (Advanced Testing Services Inc), with 28 years of military and civilian testing experience, conducted the testing. Test results establishing Mil STD 188-125 shielding compliance are below:

1.5 Executive Summary

MIL-STD-188-125-1 Appendix A acceptance testing was performed on one RF shielded enclosure, the OTS Integrated Shielded Test Structure known as OTS ISTS. This testing took place at Omni-Threat Structures located in Lakeland, Florida. Testing took place on December 4, 2019. with no deviations of MIL-STD-188-125-1 Appendix A. The OTS ISTS under test successfully satisfied all pass/fail criteria specified.

2.0 OTS Integrated Shielded Test Structure Description

The OTS Integrated Shielded Test Structure consists of a 10 inch thick cube of OTS proprietary, licensed conductive concrete mix with two embedded shielding grids. The approximate dimensions of the OTS Integrated Shielded Test Structure are 8’ x 8’ x 10’. One RF door and four WBC pipe penetrations installed as part of the RF shield barrier.